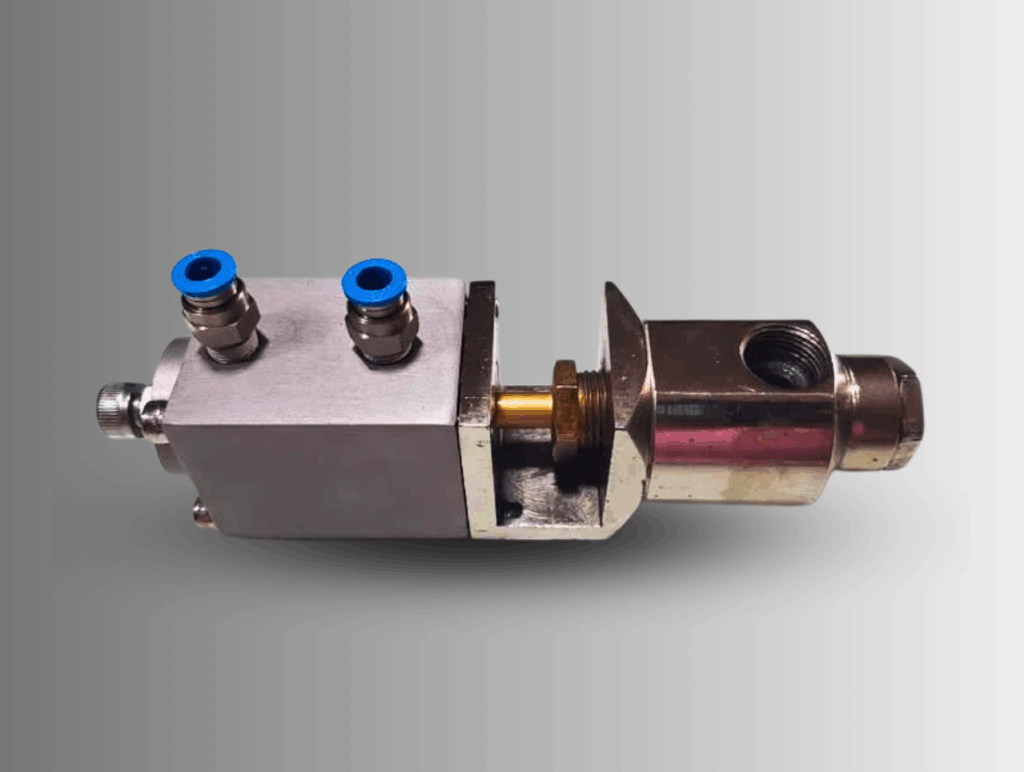

Spool type dispensing valves

Features

- Instant cut-off of fluid.

- Lightweight SS construction.

- Compression fittings and tubing.

- Low maintenance design.

Specifications

- Fluid in Port: - 3/8” BSP (F)

- Fluid Out Port: -¼” BSP (F)

- Air Port: -1/8" BSP (F)

- Air Pressure: -4 to 7 Kg/cm2

- Max. Inlet Fluid Pressure: - 10 Kg/cm2

- Viscosity: - 1 cps to gel

- Dispensing Head: -90 degrees

Application

- Anaerobic & UV Curing Adhesives, Rubber glue including silicones, sealants, grease, PVC Sealant and All type of oils etc.

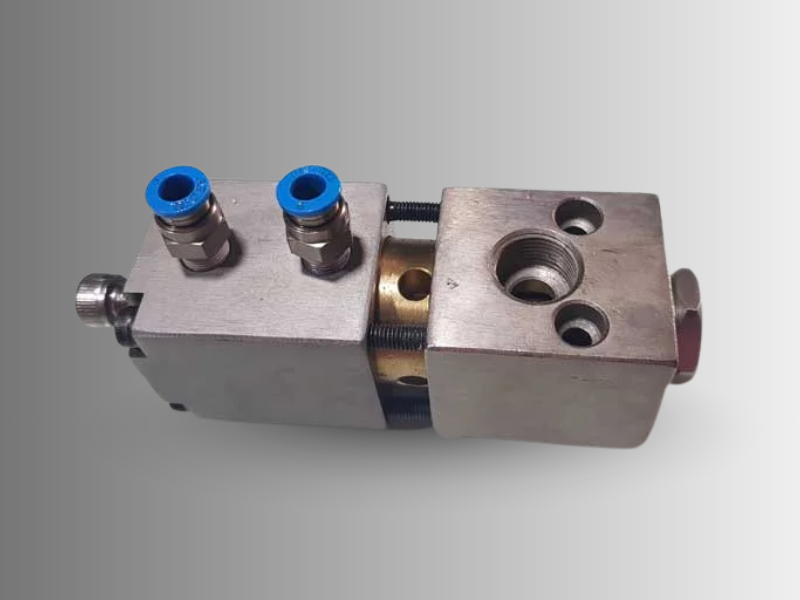

spool type compact dispensing

Features

- Instant cut-off of fluid.

- Lightweight SS construction.

- Compression fittings and tubing.

- Low maintenance design.

Specifications

- Fluid in Port: - 3/8” BSP (F)

- Fluid Out Port: -¼” BSP (F)

- Air Port: -1/8" BSP (F)

- Air Pressure: -4 to 7 Kg/cm2

- Max. Inlet Fluid Pressure: - 10 Kg/cm2

- Viscosity: - 1 cps to gel

- Dispensing Head: -90 degrees

Application

- Adhesives, Rubber glue including silicones, sealants, grease, PVC Sealant and All type of oils etc.

mini dispensing valves

Features

- Instant cut-off of fluid.

- Lightweight SS construction.

Specifications

- Fluid in Port: -1/8” BSP(F)

- Fluid Out Port: -¼” BSP (F)

- Air Port: -M5(F)

- Air Pressure: -4 to 7 Kg/cm2

- Max Fluid Pressure: -7 Kg/cm2

- Viscosity: - 1 cps to flow able glue.

- Dispensing Head: -90 degrees

Application

- Adhesives, Rubber glue including silicones, sealants, grease, PVC and All type of oils etc.

pinch tube valves

Features

- Instant cut-off of fluid.

- Light weight construction.

- Compact size and weight.

- Simple to operate.

Specifications

- Fluid in Port: -From ID φ6 &φ8mm Tube

- Fluid Out Port: - From ID φ6 &φ8mm Tube with nozzle adapter

- Air Port: -M5(F)

- Air Pressure: -4 to 7 Kg/cm2

- Max Fluid Pressure: -2 Kg/cm2

- Viscosity: - 1 cps to 1000 cps

- Dispensing Head: -Straight inline

Application

- Anaerobic & UV Curing Adhesives, Rubber glue including silicones etc.

recirculation valves

Features

- Suck back feature to prevent stringing of dispensed materials.

- Lightweight SS construction.

- Compact size and weight.

- Simple to operate.

Specifications

- Fluid in Port: - 3/8” BSP(F)

- Fluid OutPort: - ¼” BSP(F)

- Air Port: - 1/8” BSP(F)

- Air Pressure: - 4 to 7 Kg/cm2

- Max Fluid Pressure: - 7 Kg/cm2

- Viscosity: - 100 cps to 3000 cps

- Dispensing Head: - 90 degrees

Application

- Polyurethane, Isocyanate, Epoxy, hardener, etc.

pinch tube valves with roundbody

Features

- Suck back feature to prevent stringing of dispensed materials.

- Lightweight SS construction.

- Compact size and weight.

- Simple to operate.

Specifications

- Fluid in Port: -¼” BSP(F)

- Fluid Out Port: -¼” BSP(F)

- Air Port: -M5(F)

- Air Pressure: -4 to 7 Kg/cm2

- Max Fluid Pressure: -2 Kg/cm2

- Viscosity: - 100 cps to 3000 cps

- Dispensing Head: -Straight inline

Application

- Adhesives, Rubber glue including silicones, sealants, grease, PVC and All type of oils.

About JAL Automations

JAL Automation & Systems is a leading manufacturer and supplier of fluid dispensing systems and equipment. We specialize in advanced technology, production, and marketing of automated fluid dispensing solutions for diverse industries.

Address

- Ahmedabad

- Bengaluru

- Chennai

- Faridabad

- Hyderabad

- Pune

- Maharashtra

- India

- Noida

- Gurgaon

- Delhi

- Punjab

- Ludhiana

- Chandigarh